Sepette ürün yok.

Sepetiniz

×İhtiyaçlarınıza yönelik doğru ürünün seçimini uzman ekibimizle kolaylaştırıyoruz.

Meraklı mı hissediyorsun? SSS'lerimizden bazılarını okuyun veya yardım için destekçilerimizle iletişime geçin

Panel kapıların içlerindeki ağaç karkas kısmı kapı serenidir.Serenler köşelerinden birleştirilerek içine arı peteği şeklinde kağıt petek konulup kapı karkası yapılır.

Kapı; seren, petek ve panelden oluşmaktadır. Fakat en önemli görev ahşap kısmına yani ahşap serene aittir. Kapı yapımında kullanılacak serenler çerçeve haline getirilir.

Serenden yapılmış çerçevenin içine dolgu malzemesi olarak kapı peteği yerleştirilir ve kapı panelini her iki yüze de yapıştırma kaidesiyle preslenir ve kapı kanadı oluşmuş olur. Buna göre kapı sereninin önemi çok büyüktür

Kapı sereninin üzerinde pres esnasında oluşan ve sıcaklıkta genleşen havanın pres kalitesini olumsuz şekilde etkilememesi için kanallar açılır. Isınan hava bu kanallar yardımıyla kapı sereni üzerinden atılarak düzgün bir pres ve yapıştırma yüzeyinin sağlanmasında çok etkilidir.Genellikle 5x5 mm hava kanalı açılır.

Lamine, lamine kiriş, mobilya, kapı, ahşap masif panel ( finger jointli malzeme ), çardak, pergule, çocuk oyuncakları, montessori çocuk yatak gibi birçok alanda kullanılır.

Kapı sereni üretimi için kullanılacak en iyi ağaç ladin keresteden üretilendir. Çam ve ladinde bulunan yüksek nem oranı kapı sereni ve kapıları daha güçlü hale getirir.

Dengesiz hava koşullarına bağlı oluşan nemden yamulma meydana gelir.Tamamen budaklarından ayrılmamış finger jointli malzemede budak kaynaklı yamulmalar olabilir.

Tomruğun istenilen ebatlarda biçilerek 4 köşe hale getirilmesine,yani işlem görmesinden sonra oluşan mamüle kereste denir.

Kerestede ölçülen kalınlık x genişlik x boy ölçüsü net ölçüdür.

Kerestenin kalınlık x genişlik x boy ölçüldüğünde boya eklenen testere payıdır.

Fırınlandıktan sonra 4 tarafı planyalanan kerestedir.

Ağacın çeşidi,yetiştiği bölge,yetişme,büyüme yılı,kesim şekli,fırınlanması,fırınlandıktan sonra saklama koşulları,kerestenin sınıflandırılması ve fiyatı keresteyi kaliteli kılan faktörlerdir.

Isıl işlem yapıldıktan sonra kereste üzerine IPPC(Uluslararası Bitki Koruma Konvansiyonu)damgasının vurulmasıdır.

- Tahta doğal bir hammaddedir.

- Dayanım / ağırlık oranı bakımından ekonomik bir yapı malzemesidir.

- Üretimi hızı konusunda hızlıdır.

- Fiyat konusunda diğer ambalajlama türlerine göre daha uygundur.

- İstiflenebilme özellikleri iyidir.

Ahşap ambalaj, geçmişten günümüz gelen, ürün ambalajlama yöntemlerinden en güncel ve en önde gelen ambalajlama çeşididir. Günümüzde de yoğun olarak kullanılmaktadır. Ahşaptan yapılan malzemelerin esnek, dayanıklı, gibi geleneksek özelliklerinin yanında, kısmen veya tamamen tamir edilebilmesi, artıklarının doğada hızlı çözülebilmesi, önemli avantajlar olarak ortaya çıkıyor. Ahşap ambalaj; her türlü ahşap palet, ahşap kasalar (sandıklar), OSB Kasa ve sandıklar, kontrplak kasa ve sandıkları gibi birçok ürünü kapsar.

Türkiye nin 80 li yıllardan bu yana artan ihracat hacminde, öncelikle bazı sektörlerde olmak üzere 90 lı ve 2000 li yıllarda, birçok sektörde çeşitlilik gösteren, ihracat artışlarına şahit olunmaktadır. Dünya’ya ürün satabilmek için, ürününüzün kaliteli ve sağlam olarak müşterilere ulaşması şarttır. Bu durumu çok iyi idrak etmiş şirketler, ürünlerini çarpma, sarsıntı, nem gibi dış etkilerden korumak için konteynerler içerisinde sabitlenmesi ve hacim olarak tam dolmasını sağlamak amacıyla bu konuda, hem dayanıklı, hem hafif hem de uygun maliyetleri sebebiyle sevkiyatları için ahşap ambalaj (ahşap sandıklar, ahşap paletler) kullanırlar.

Ahşap Ambalaj üretiminde, her müşterinin ihtiyacı farklı olabilir. Önemli olan müşterinin ihtiyacını tam olarak anlayabilmektir. Bu sebeple her ürün için en uygun ahşap ambalajı yapmak üzere, ürün üzerinde çalışarak, detay ölçülerini almak gerekir. Ayrıca sabitleme ihtiyacı için ek ahşap profiller, ahşap takozlar ve ahşap direkleri de göz önüne alarak, etkin bir ahşap ambalaj geliştirmek gerekir. Müşterinin ihtiyacını en hızlı şekilde karşılayabilecek maliyet açısından da en uygun olacak şekilde kapalı ahşap sandık, OSB kapalı sandık, ızgara (kafes) sandık,Vinç aparatlı sandık gibi sandık çeşitlerine karşılıklı olarak karar verilir ve üretime başlanır.

Ahşap ambalajların hijyeni de, plastik kasalara göre daha iyidir. Birim alanda biriken bakteri sayısı, muadil plastik palet ve plastik kasalara göre çok daha azdır. Günümüz salgını COVİD19 virüsünün ahşap üzerinde plastik ve metal kasalara göre daha kısa süre yaşadığı bilinmektedir.

Üretim hızı ve fiyat konusunda da diğer ambalajlama türlerine göre daha çok tercih edilir.

Malzemelerin istiflenip sevk edileceği noktaya kadar ürünü alttan destekleyen iki taraflı forklift girişi olan palet türüdür. Standart ölçüsü 800*1200 mm dir.

(International Standart for Phytosanitary Measures) Uluslararası ticarette kullanılan ahşap ambalaj malzemeleri ile ilgili zararlıların bulaşması ve yayılması riskinin azaltılması için alınması gereken Bitki Sağlığı önlemlerini açıklar.Isıl işlem fırınlarında, fırınlama yaparak ahşabın çekirdek ısısının 56 dereceye geldikten sonra 30 dk. bekletilerek ahşabın içindeki zararlı böceklerden ve larvalardan arındırılması işlemidir.

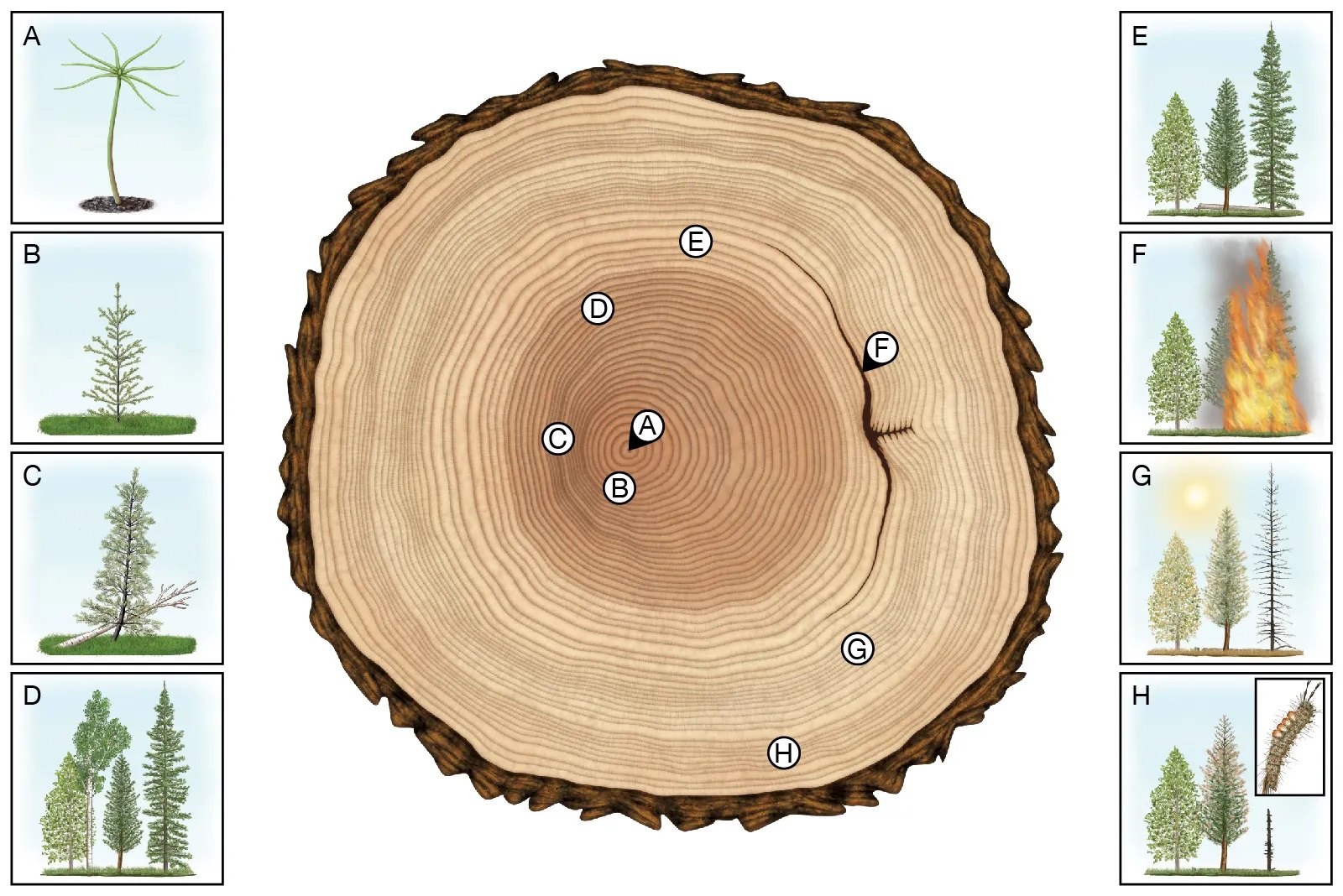

Ahşap, canlı bir organizma olan ağaçtan elde edilen lifli, heterojen ve anizotrop bir dokuya sahip organik esaslı bir yapı malzemesidir. Ahşap, en eski yapı malzemelerinden birisidir. İnsanoğlu ahşabı eski çağlardan beri barınma ve korunma amaçlı olarak kullanmaktadır. Günümüzde ormanların çeşitli nedenlerle azalması, yerine yenisinin yetiştirilememesi veya geç yetişmesi ahşabın değerini arttırmıştır. Ahşap; çatı elemanları, doğrama ve kaplama malzemesi, kalıp ve iskelelerde taşıyıcı ve dekoratif malzeme olarak kullanılmaktadır. Ayrıca bugün ahşabın atıkları olan yonga, talaş ve tozlarından da üretilen sunta, MDF, kontrplak gibi yapay yapı malzemeleri vardır. Ahşabın kesilerek standart boyutlara getirilmiş haline ise kereste denir.

Ahşap, nispeten daha kısa zamanda, 25 ila 80 yıl arasında yeniden büyüyebilir ve yenilenebilir. Tuğla, beton ve çeliğin hammaddeleri ise ancak bir jeolojik zaman geçtikten sonra yenilenebilir.

Ahşabın karakteri yaş, çevresel faktörler, nasıl bakıldığı ve kullanım tercihine göre çeşitlenir. Yer altındaki minerallerin nitelikleri ise “insan” zamanı için önemli ölçüde değişmez.

Kısacası ahşap yenilenebilir, geri dönüştürülebilir, çevre dostu ve estetik açıdan özgünlüğü tartışılmaz bir hammaddedir. Bilinçli bir şekilde hasat edilmiş ve yerine genç ağaçlar dikilmiş ahşaptan üretilmiş ürünler kullanmak, dünyaya bir iyilik yapmaktır.

Yıllardır bizimle çalışan müşterilerimizden bilgi alın.

CNRWOOD ile iş yapmak gerçekten keyifli. 1998 yılından beri ahşap sektöründe liderliklerini koruyorlar. Kapı sürgüleri ve laminat kirişler konusundaki uzmanlıkları sayesinde uluslararası alanda güvenilir bir marka haline geldiler. Her zaman kalite ve müşteri memnuniyeti odaklı bir işbirliği yaşadık.

İşte CNRWOOD ile çalışmanın ayrı bir zevki var. Onlar, 1998'den beri ahşap sektöründe liderliklerini sürdürüyorlar. Kapı sürgüleri ve laminat kirişler konularındaki uzmanlıkları sayesinde uluslararası alanda güvenilir bir marka olmayı başardılar. İşbirliklerimiz her zaman kalite ve müşteri memnuniyetine odaklı oldu.

CNRWOOD ile iş yapmak ayrı bir zevk. 1998'den beri ahşap sektöründe liderler. Kapı sürgüleri ve laminat kirişlerde uzmanlar. İşbirliklerimiz her zaman kalite ve müşteri memnuniyetine odaklı.

CNRWOOD ile iş yapmak ayrı bir keyif. 1998'den beri ahşap sektöründe liderlikleri kesin. Kapı sürgüleri ve laminat kirişlerdeki uzmanlıkları sayesinde uluslararası alanda güvenilir bir marka haline geldiler. Her zaman kalite ve memnuniyet odaklı bir işbirliği yaşadık.

6 mm veya daha ince ahşap malzemeden yapılan ambalajlar